Introduction

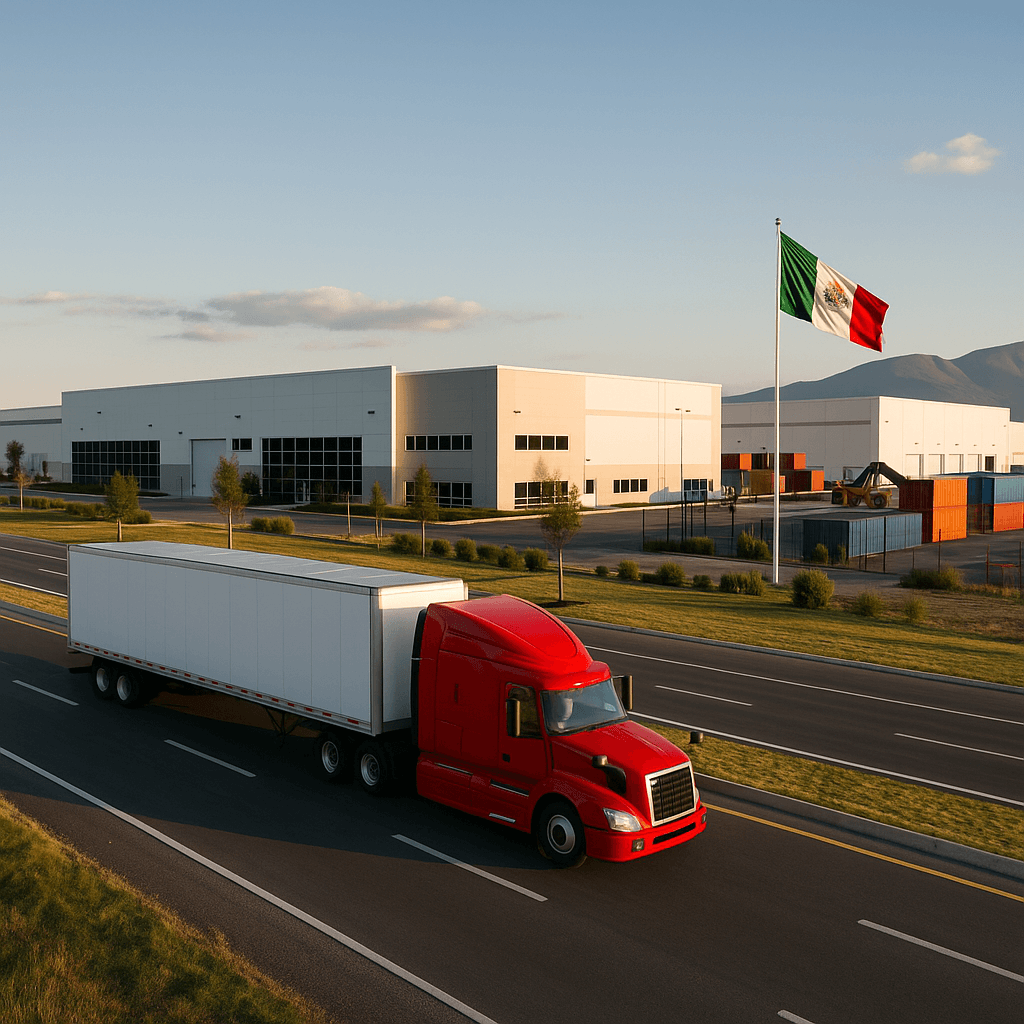

Nearshoring to Mexico has become a top strategy for companies that want to reduce dependency on China and bring production closer to the U.S. market. With the advantages of the USMCA trade agreement, competitive labor, and strong manufacturing clusters, Mexico is attracting attention from every industry — from automotive and plastics to food processing and electronics.

However, the transition is not always smooth. Many companies underestimate how different it is to source products in Mexico or to move manufacturing to Mexico compared to Asia or the U.S.

As a sourcing agent and consultant in Mexico, we’ve seen what works — and what doesn’t. Below are the seven most common mistakes companies make when starting a nearshoring or soft-landing project in Mexico, and how to avoid them.

1. Treating Mexico Like “the Next China”

Mexico is not a low-cost copy of China. The manufacturing landscape here is based on medium-sized, often family-owned companies that value personal relationships, flexibility, and reliability over volume and price.

If you treat local suppliers like anonymous factories on Alibaba, you’ll quickly lose traction.

Tip: Approach Mexico with a partnership mindset. It’s about collaboration and trust, not only cost. A good sourcing consultant in Mexico will help bridge the gap between your expectations and local business culture.

2. Overlooking Regional Strengths

Mexico is vast and diverse. Monterrey is known for metalworking and industrial automation, Guadalajara for electronics and plastics, Querétaro for aerospace and automotive, and León for leather and textiles.

Choosing the wrong region can add cost and complexity.

Tip: Work with a nearshore agent or sourcing expert who understands regional ecosystems. At Nearshore Mexico Sourcing, we match each project with the right manufacturing cluster and supplier base to save time and money.

3. Assuming Proximity Automatically Means Speed

Many companies believe that because Mexico is close to the U.S., delivery will be instant. But if your local supplier imports steel from Korea or resins from China, you’re still tied to global logistics. Customs procedures, holidays, and communication style also play a role.

Tip: Before launching production, map the full supply chain — including imported materials. An experienced sourcing agent in Mexico can help verify local content and minimize lead-time surprises.

4. Weak Communication and Follow-Up

In Mexico, relationships are everything. Projects move forward through consistent communication, personal visits, and ongoing follow-up. Many U.S. or European buyers lose momentum because they rely solely on email and expect immediate replies.

Tip: Communicate regularly by phone or WhatsApp, and confirm key points in writing. If you don’t have local presence, hire a sourcing consultant or nearshore agent in Mexico to represent your interests face-to-face.

5. Skipping Legal, Fiscal, and Import Procedures

Mexico’s trade framework is powerful, but complex. Programs like IMMEX or Prosec can save huge costs — if handled correctly. Without proper structure, companies face issues with VAT refunds, import licenses, or labor compliance.

Tip: Before moving production to Mexico, consult experts in soft landing services and manufacturing transfer support. Setting up contracts, tax IDs, and import procedures properly will prevent long delays and unnecessary costs.

6. Neglecting On-Site Quality Control

Even experienced manufacturers make the mistake of assuming everything will go smoothly after a few sample photos. Quality assurance in Mexico must be proactive.

Tip: Arrange factory audits and production inspections through a trusted sourcing agent or local quality partner. This ensures specifications, tolerances, and timelines are respected from prototype to shipment.

7. Believing Labor Is Always “Cheap”

Yes, Mexico offers competitive wages — but labor is only one part of the equation. In areas like Monterrey, Querétaro, or Guadalajara, skilled workers are in high demand, and turnover can increase total costs.

Tip: Focus on long-term supplier relationships. Stability, training, and collaboration usually lead to better quality and lower total cost than chasing the lowest quote.

Conclusion

Mexico is the ideal nearshoring destination for companies that want resilient, regional supply chains — but success depends on local understanding. Avoiding these common mistakes can save your project months of frustration and thousands of dollars.

Working with a sourcing expert in Mexico gives you a major advantage. At Nearshore Mexico Sourcing, we provide complete support — from supplier scouting and audits to manufacturing transfer, contract negotiation, and soft-landing services for companies moving production to Mexico.

If you’re exploring how to move production to Mexico or need a reliable sourcing consultant, contact us today. We’ll make sure your nearshoring project starts strong and stays on track.